DTRIPLE creates new value

with AI-based intelligent smart factory solutions

DTRIPLE innovatively improves existing manufacturing processes by using advanced AI technology. We help manufacturers make optimal decisions by collecting and analyzing real-time data from production sites, predicting quality issues, and preventing defects from spreading to subsequent processes. Through RPA (Robotic Process Automation), repetitive tasks are automated, maximizing workforce efficiency.

These solutions allow manufacturing companies to improve productivity, strengthen quality control, reduce costs, and establish a responsive and flexible decision-making system to adapt to rapidly changing market conditions. Thus, DTRIPLE’s smart factory solutions open a new paradigm for the manufacturing field.

SMART MES

ERP / RPA / OCR / AI Vision

MES (Manufacturing Execution System)

Through the automation of repetitive and routine tasks using Artificial Intelligence (AI) and Robotic Process Automation (RPA) within the Manufacturing Execution System (MES), we achieve comprehensive smart integration of production and quality management across the enterprise. This optimizes the overall operations of the factory and the company, making it an essential solution for improving productivity, reducing costs, and enabling swift decision-making.

Data collection, Analysis,

and Real-Time Monitoring

Collects and analyzes real-time data from the manufacturing site to support production planning, process optimization, and quality prediction decisions. Real-time monitoring also allows for quick problem-solving and response.

AI-based intelligent

Smart Factory Solutions

By utilizing advanced AI technology, manufacturing processes can be innovatively improved. Enhancing productivity, reducing costs, and enabling quick decision-making which can strengthen a company’s competitiveness.

Automation through RPA

By automating simple and repetitive tasks with Robotic Process Automation (RPA), employees can focus on strategic and valuable tasks.

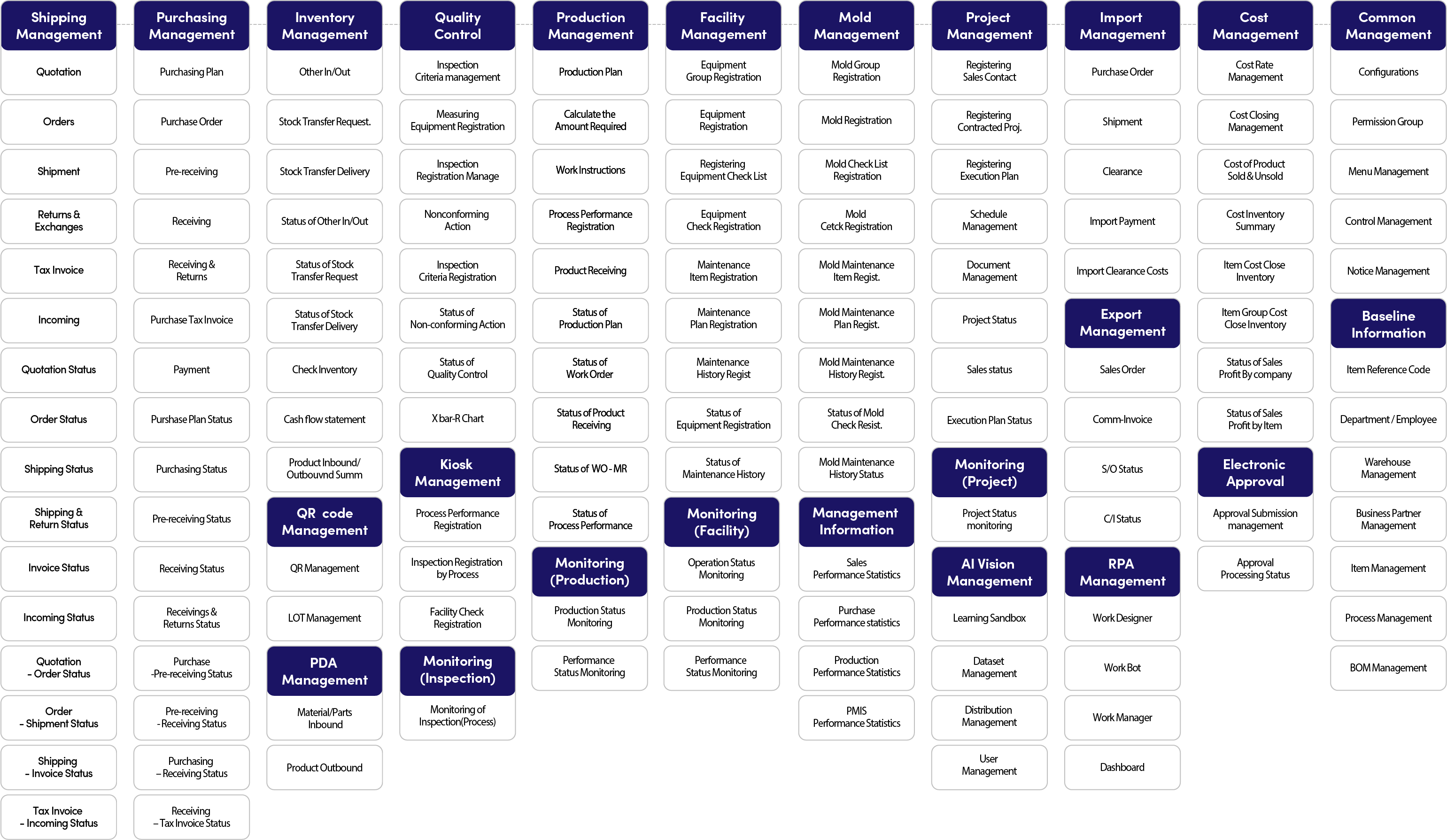

MES Advanced Data Collection, Analysis, Monitoring

DTRIPLE MES-based AI Vision, Data Collection System provides a comprehensive solution for data collection, analysis, and monitoring in advanced manufacturing environments. The system utilizes artificial intelligence and machine learning technologies to maximize production line efficiency and improve quality.

Smart-MES Integrated Menu Structures

PMIS

RPA / MES / Cost

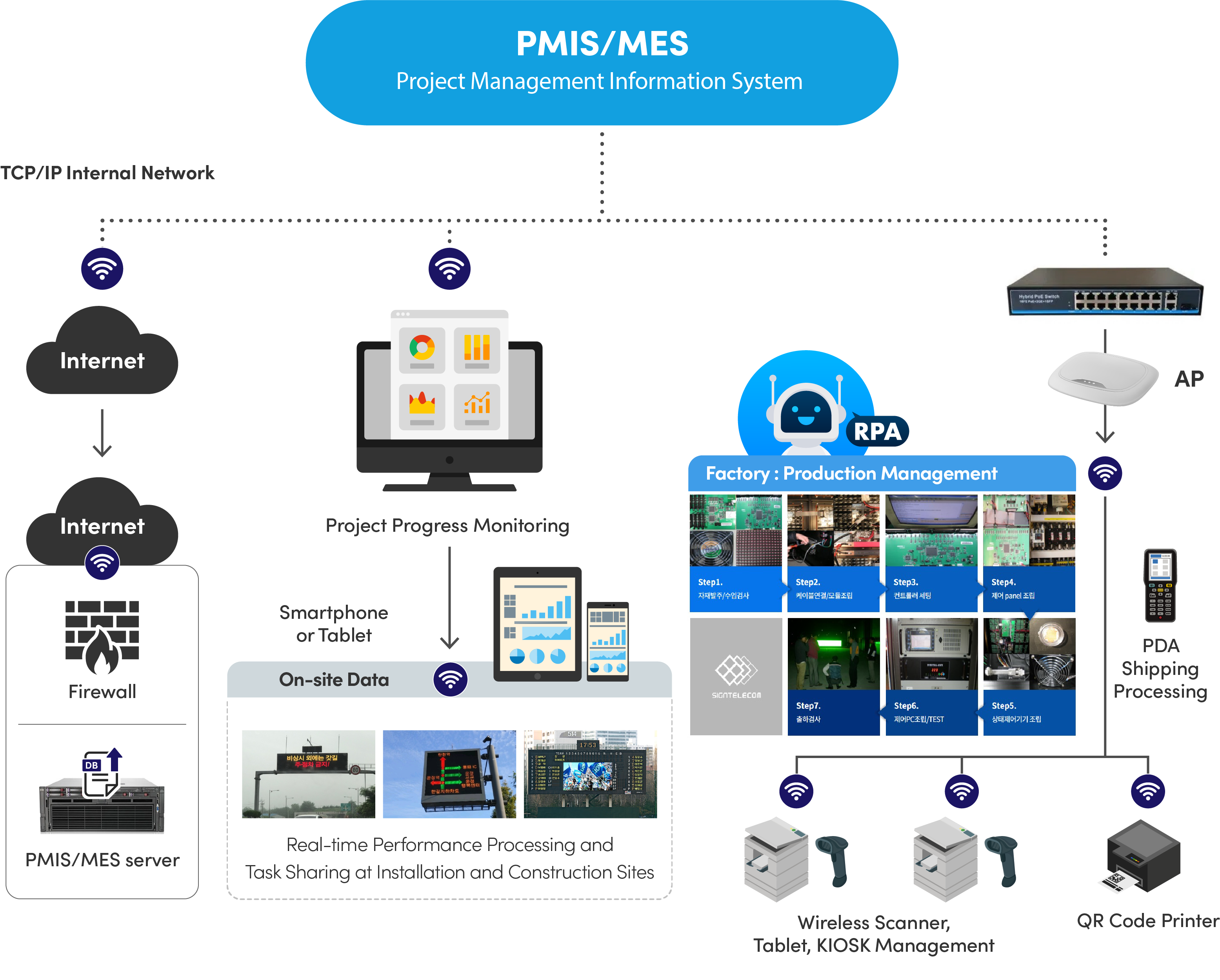

PMIS(Project Manageent Information System)

The PMIS integrated with MES supports efficient project management for manufacturing companies by combining real-time production data and project management functions, systematically managing the entire project process. By applying RPA to repetitive tasks such as scheduling, resource management, cost, and reporting, project managers can focus on strategic decision-making, contributing to enhanced performance with proactive monitoring and quick response systems.

Integrated Management System

The integration of MES and RPA allows systematic management of the entire project through data and process automation at the production site.

Real-Time Information Access

Combines on-site data and project information into real-time monitoring, supporting swift decision-making.

Cost Reduction

and Productivity Improvement

Optimizes the use of resources such as personnel, materials, and equipment through process automation and data analysis, leading to cost savings and productivity enhancements.

PMIS / MES / RPA (Project Management Information System)

WMS

AMR / AGV / ACS / Stacker

Advanced Automated Warehouse Management System

DTRIPLE has developed a smart warehouse management solution using advanced stackers and Autonomous Mobile Robots (AMR). This system enables real-time inventory tracking and fully automates the inbound, outbound, and storage operations within the warehouse.

The stacker system allows for efficient loading and rapid handling of goods, while AMRs automate the movement of items within the warehouse, reducing labor costs and enabling fast delivery. All these functions are integrated into a comprehensive management system, significantly enhancing the efficiency and productivity of warehouse operations.

Advanced Automation

Intelligent robots and IoT sensors fully automate tasks such as receiving, inventory management, and dispatching, reducing work time, errors, and enhancing productivity.

Real-Time Data Management

Collects and analyzes data from all products and equipment in real-time to achieve optimal inventory control and logistics flow.

Autonomous Transport

AGVs/AMRs transport goods safely and efficiently, minimizing worker movement and optimizing logistics.

ACS (AGV Control system)

QMS

AI Vision / 3D AI Vision

Intelligent (AI) Vision Quality Management System

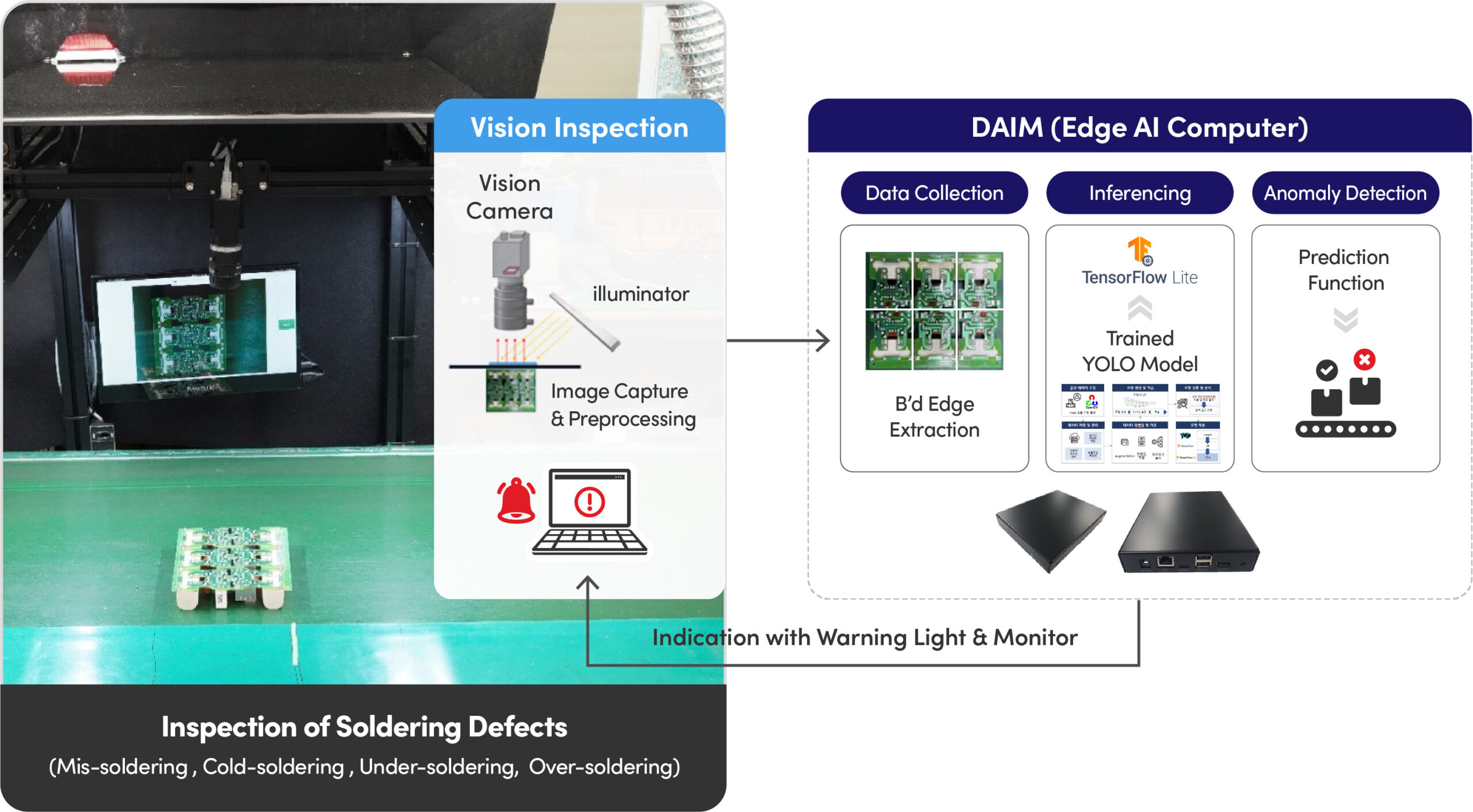

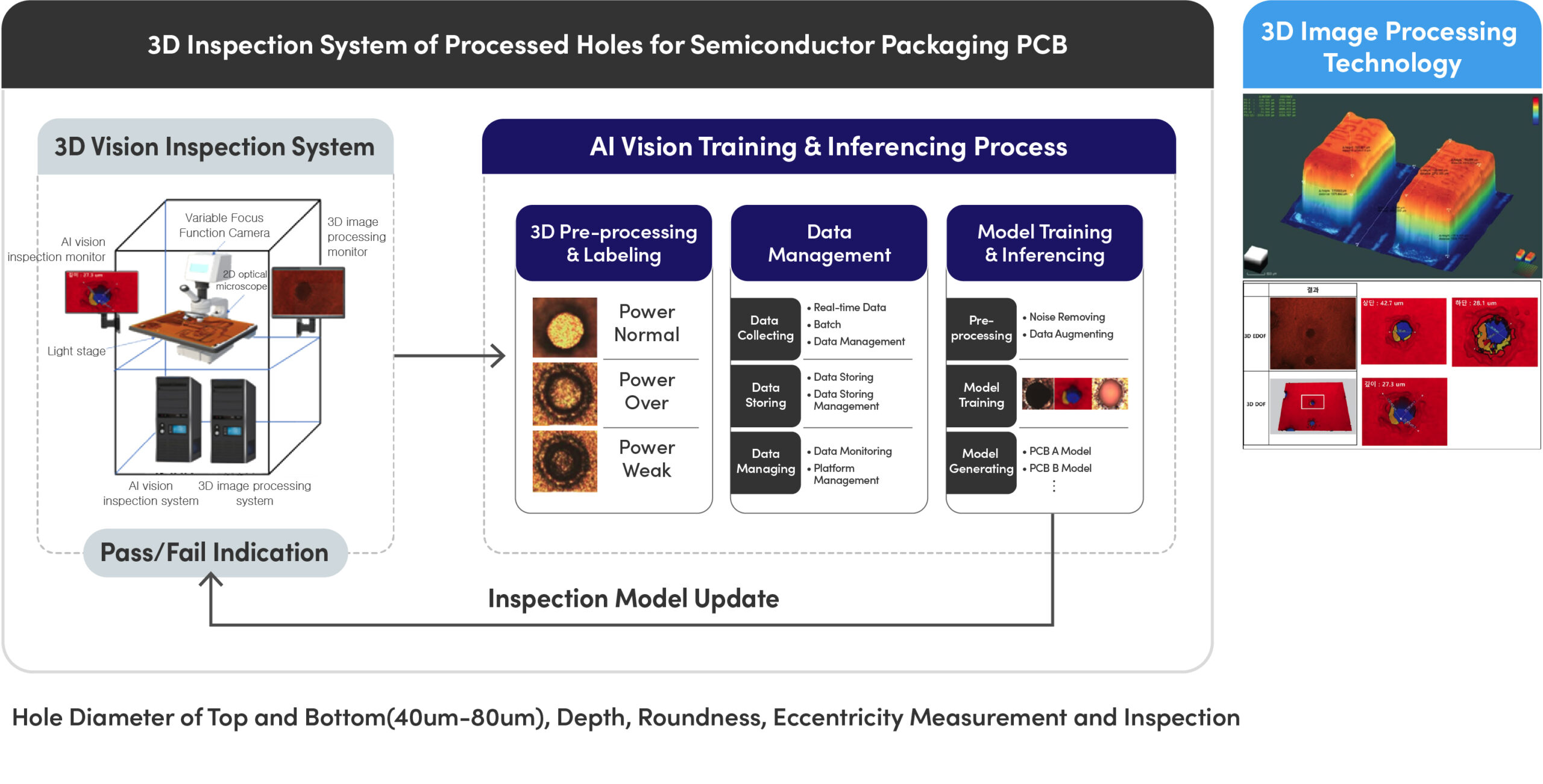

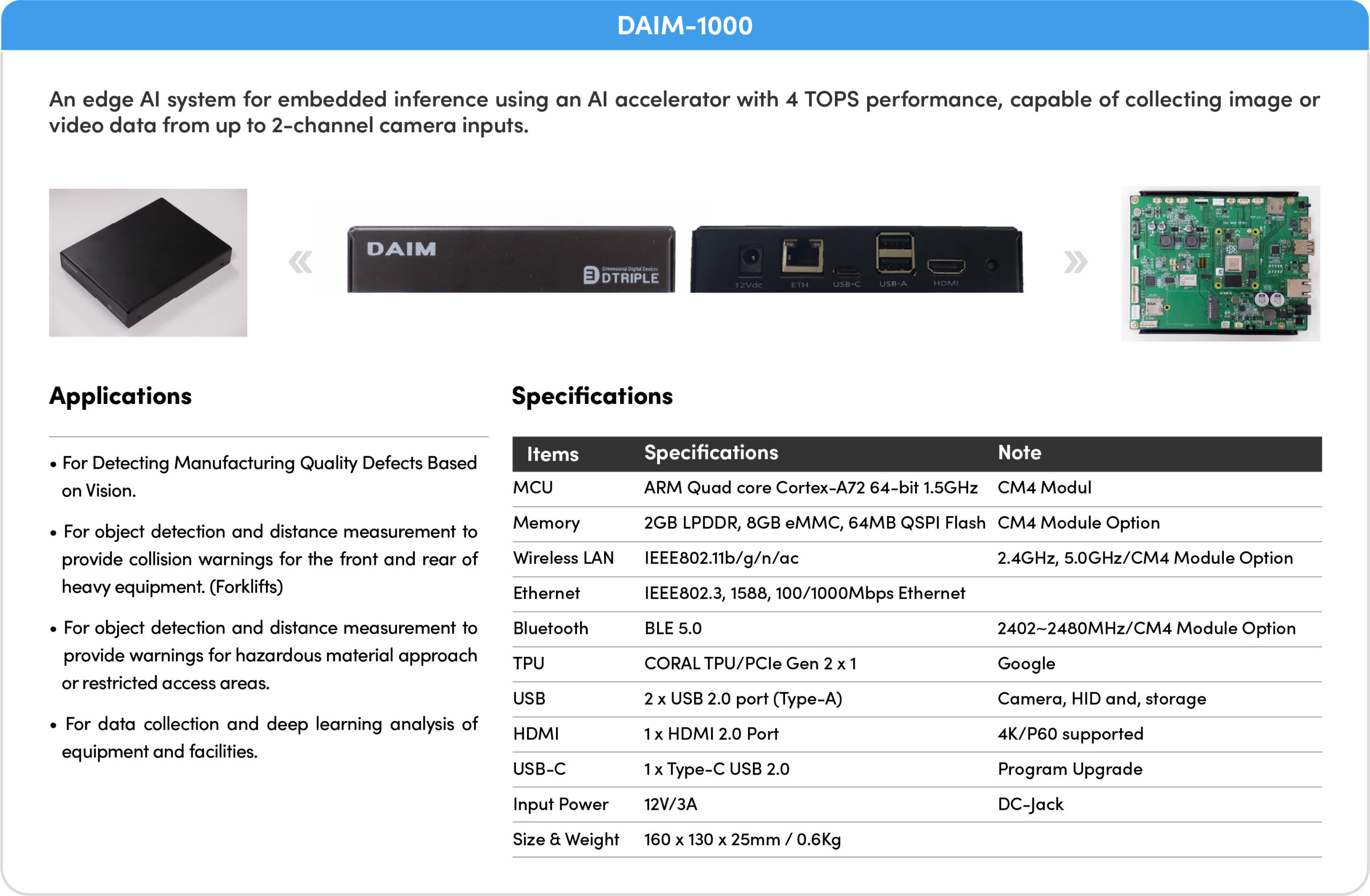

The intelligent vision quality management system significantly improves quality control accuracy and efficiency by identifying minute defects that are diffcult to detect with the human eye. Collected data is also used to continuously improve production processes. Integrated with MES, this system enables real-time management of production volume and quality level, enhancing productivity and external quality competitiveness.

Real-Time Quality Data Collection

AI-based vision inspection technology collects and analyzes image data in real time during the production process, supporting defect detection.

Integration with MES and AI Vision

Integrated with MES and a framework that supports data collection, AI learning, and inference, this system automates defect inspections without human intervention.

AI-Based Process Optimization

Continuous improvement and optimization of production processes using accumulated big data and the latest AI algorithms, enhancing productivity, yield, and cost savings.

PBA Soldering Defect Inspection System

Semiconductor Packaging PCB 3D AI Inspection System

Edge-AI System DAIM(DTRIPLE AI Module)

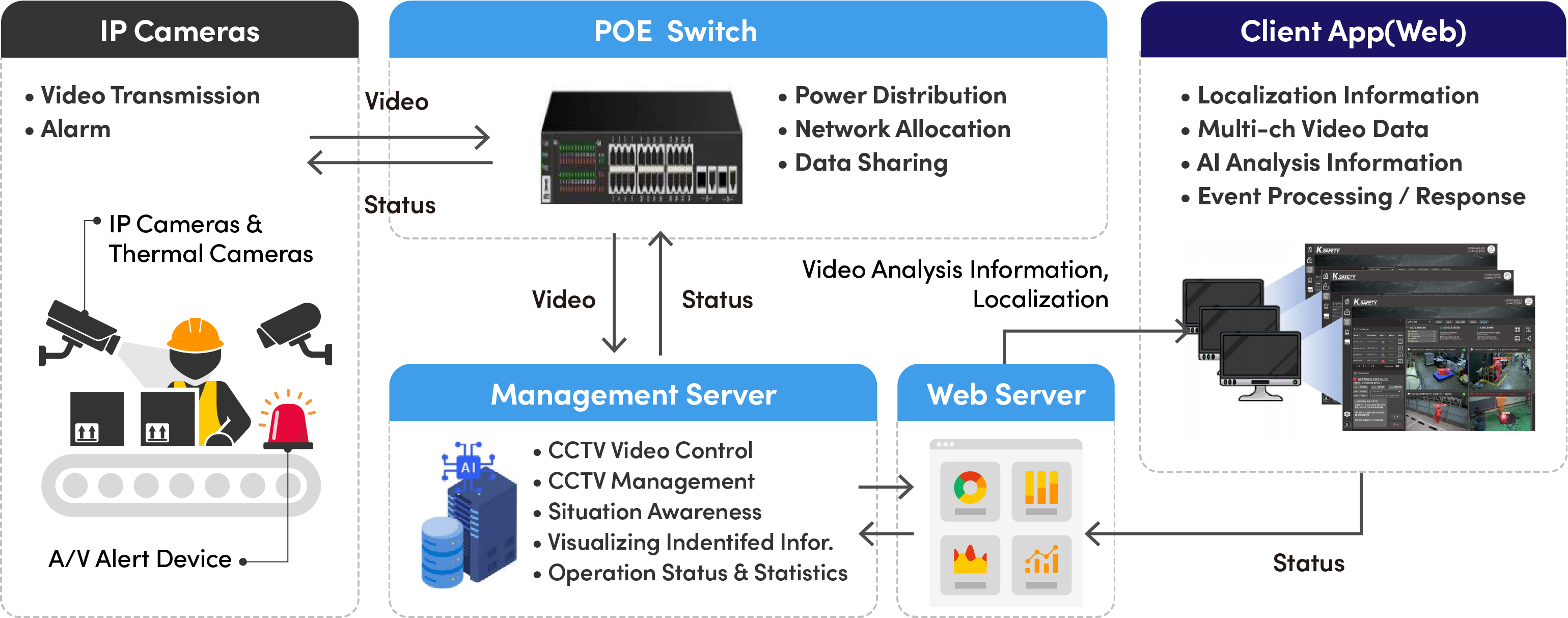

Industrial Safety

Industrial Safety Solutions

DTRIPLE has developed a smart safety solution prioritizing worker safety. This solution uses smart bands worn by workers to collect real-time biometric and location data, allowing for immediate monitoring of workplace hazards, instant warnings, and responsive actions. It automatically records worker activities, accumulating safety management data that helps predict potential risks and take preventive measures, thus enhancing safety and preventing accidents.

By utilizing advanced IoT technology, DTRIPLE’s smart safety solution significantly improves the safety of manufacturing sites, offering both worker protection and productivity enhancement.

Real-Time Risk Detection & Safety Management System

This solution combines cameras and IoT sensors to prevent accidents and ensure the safety of workers in manufacturing facilities, as well as to provide rapid response in case of an incident. The determination of abnormal situations, such as accidents or disasters, is automatically performed by AI. The integrated control system manages the dissemination of incident information, evacuation, rescue efforts, and emergency response to prevent the spread of accidents.

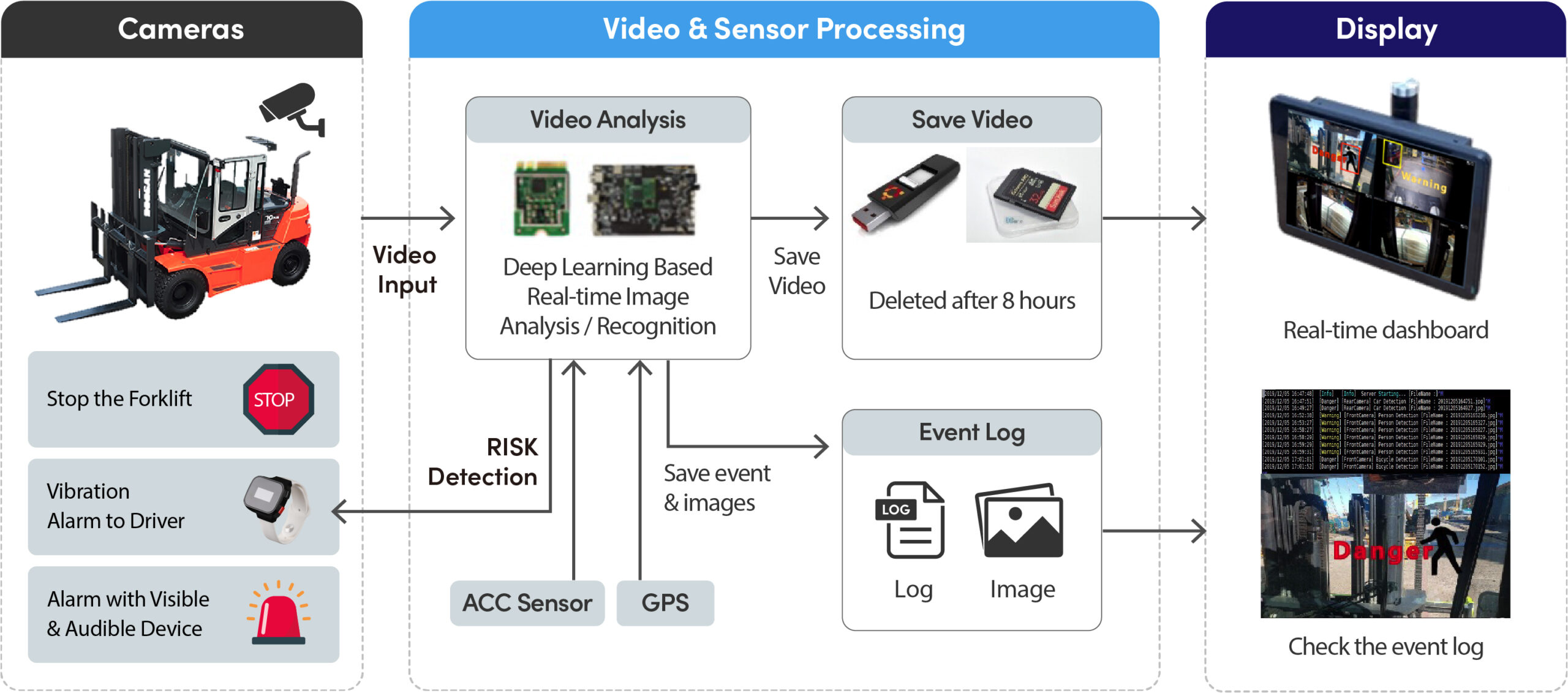

Forklift Safety Alert System

DTRIPLE has developed a smart safety solution for the forklift. This solution analyzes camera footage using deep learning (DL) to identify approaching moving objects (vehicles, people) and triggers alerts. It is essential for ensuring the safety of forklift operators, using sensors to prevent tipping due to excessive loads. Additionally, it can be integrated with MES, ACS, and the factory-wide integrated safety management system.

Consulting Service

Smart Factory Construction Consulting

DTRIPLE offers customized consulting services based on rich experience in smart factory implementation, supporting the entire process of building smart factories, including production site analysis, technology application strategies, and step-by-step implementation planning.

Building a smart factory is an essential task for enhancing the competitiveness of manufacturing companies. Through our professional consulting services, we will support your journey towards establishing a smart factory.

On-Site Diagnosis

A team of experts will visit the factory to assess the current state and identify areas for improvement.

Customized Solution Design

Tailor-made smart factory solutions are designed to meet the specific characteristics and needs of each industry.

Implementation and Training

Optimized smart factory solutions are implemented, and necessary training is provided to ensure smooth application.

Case Study

Major Business Partners

DTRIPLE provides comprehensive smart factory solutions across various industries, enhancing productivity, quality control, and safety through advanced AI, RPA, and IoT technologies. Our solutions have been successfully implemented in numerous companies, driving innovation and competitiveness in the manufacturing sector.